OPTICAL PROJECTORS

|

|

|

Also known as an optical comparator, a profile projector is an optical instrument that can be used for measuring. It is a useful item in a small parts machine shop or production line for the quality control inspection team.

A Profile projector is widely used for complex shape stampings, gears, cams, threads and comparing the measured contour model. A Profile projector is easy to use and highly efficient. Profile projectors are commonly used measurement of optical instruments. Thus, profile projector is widely used in major machinery & engineering & manufacturing including aviation, aerospace industry, watches and clocks, electronics, instrumentation industry, research institutes and detection metering stations at all levels , etc.

|

|

|

|

The profile projector magnifies the profile of the specimen, and displays this on the built-in projection screen. On this screen there is typically a grid that can be rotated 360 degrees so the X-Y axis of the screen can be aligned with a straight edge of the machined part to examine or measure. This projection screen displays the profile of the specimen and is magnified for better ease of calculating linear measurements.

On the profile projector, it magnifies the

profile of the specimen, and displays this on the built-in projection

screen. On this profile projector screen there is typically a grid that

can be rotated 360 degrees so the X-Y axis of the screen can be aligned

with a straight edge of the machined part to examine or measure. This

projection screen displays the profile of the specimen and is magnified

for better ease of calculating linear measurements.

An edge of the

specimen to examine on the profile projector may be lined up with the

grid on the screen. From there, simple measurements may be taken for

distances to other points. This is being done on a magnified profile of

the specimen. It can be simpler as well as reduce errors by measuring on

the magnified projection screen of a profile projector.

The typical

method for lighting is by diascopic illumination, which is lighting from

behind. This type of lighting is also called transmitted illumination

when the specimen is translucent and light can pass through it. If the

specimen is opaque, then the light will not go through it, but will form

a profile of the specimen.

Measuring of the sample can be done on

the projection screen. A profile projector may also have episcopic

illumination (which is light shining from above). This useful in

displaying bores or internal areas that may need to be measured. An edge

of the specimen to examine may be lined up with the grid on the screen.

From there, simple measurements may be taken for distances to other

points. This is being done on a magnified profile of the specimen. It

can be simpler as well as reduce errors by measuring on the magnified

projection screen of a profile projector.

The typical method for

lighting is by diascopic illumination, which is lighting from behind.

This type of lighting is also called transmitted illumination when the

specimen is translucent and light can pass through it. If the specimen

is opaque, then the light will not go through it, but will form a

profile of the specimen.

Measuring of the sample can be done on the

projection screen. A profile projector may also have episcopic

illumination (which is light shining from above). This useful in

displaying bores or internal areas that may need to be measured.

Typical Functions of a Profile Projector ;

• Multi-point collection to determine the line and circle;

• Preset the geometry elements;

• Determine the combination of various geometric elements;

• Coordinate rotation and translation;

• Z-axis can be set as length of the sensor or angle value of the encoder;

• User self-programming function;

• Polar / rectangular coordinates conversion;

• Grating linear correction, section linear correction;

• RS232 input function;

• Print page input function;

• Power-off memory function;

• The geometric elements can be stored and call on.

EP-2010 Easson Optical Projector 315mm Optical Screen

Description

EASSON EP-2010 HIGH PRECISION OPTICAL PROJECTOREP-2010 high precision optical profile projector provides accurate 2D measurement for all common geometric features such as circles, lines, angles etc. All measured results can be printed or transferred to computer for further processing.

The EP-2010 Optical Projector is designed for all circulate dimension measurements in mould and die making, form tool making, screw manufacturing, gear manufacturing etc.

Constructed with top class components and under high standard of workmanship, EP-2010 achieves very high measurement accuracy. The axial measurement accuracy is 3+L/100um, where L is the measured length in mm. The total contour distortion is less than 0.08%.

EP-2010 is equipped with ES-12P 1um resolution high accuracy measuring system which provides comprehensive and easy to use geometric measurement functions.

ES-12P GRAPHIC MEASURING SYSTEM SPECIFICATIONS

AXIS: X, Y axis liner transducer. A axis rotary encoder

RESOLUTION: 0.001mm (X,Y axis) / 0.01º (A axis)

CO-ORDINATES: X, Y and Polar Co-ordinates Systems

MEMORY: 99 feature memory, 10 co-ordinates memory

ERROR COMP: Linear and non-linear error compensation

I/O INTERFACE: RS-232C I/O interface

GEOMETRIC MEASUREMENT FUNCTIONS

Basic measurement functions: point, line, angle, circle, ellipse, distance, angle, intersection

* Pattern measurement function: Midpoint, circle tangent lines, line circle intersection, circles intersection, midline

* language can be setting to English, Italy, German, French, Portuguese, Spanish, Chinese, Czech

* Words and background color of screen can be setted

STANDARD ACCESSORIES

- Thermal Printer

- ES-12P Projector Digital Readout

- Precision Rotary Table

- Precision Lens 10x

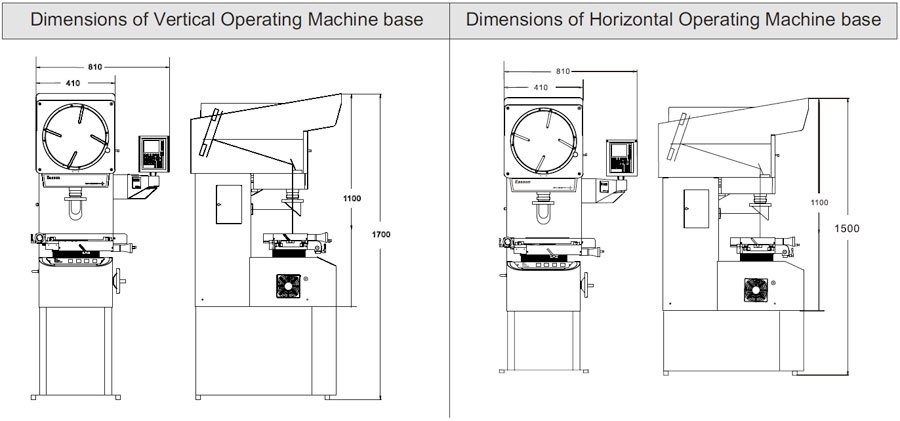

ERGONOMIC DESIGN MACHINE BASE

To make the EP-2010 the most comfortable projector to operate, EP-2010 has two options of machine base available for the user's choice. The standing operate machine base is best for shop floor usage where users are using the projector for measuring small quality of work piece individually. The sitting operate machine base is best for QC room usage where small numbers o users have to measure large quantity of work piece efficiently.

Features

- Table glass size 225 x 125mm

- Measurement travel 200 x 100mm

- 315mm Screen diameter

- 10x, 20x and 50x lens available (standard machine 10x only)

- Digital readout X, Y and A, 1um

- Thermal printer, rotary table